We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

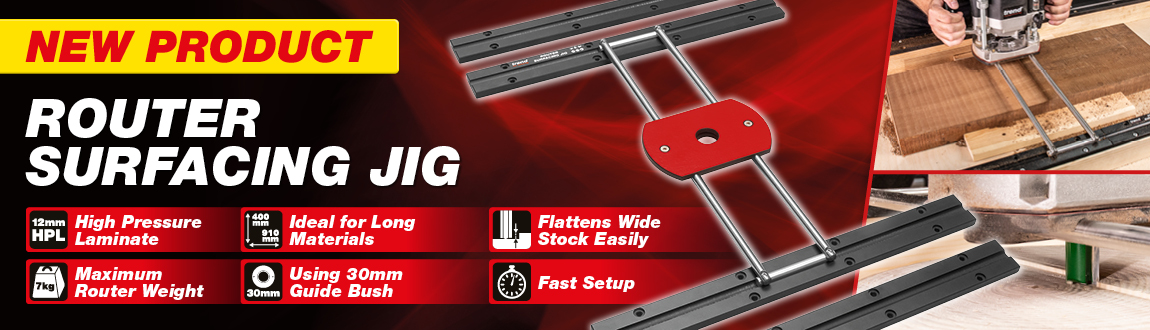

Router Surfacing jig

RS/JIG Router Surfacing Jig

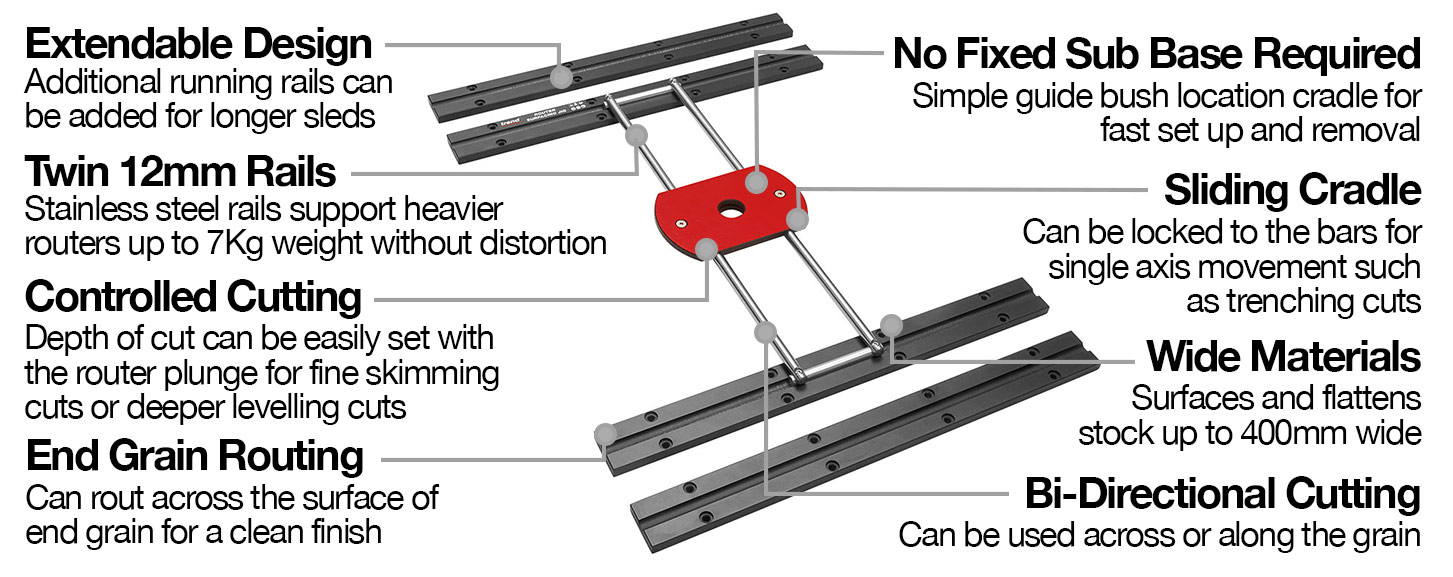

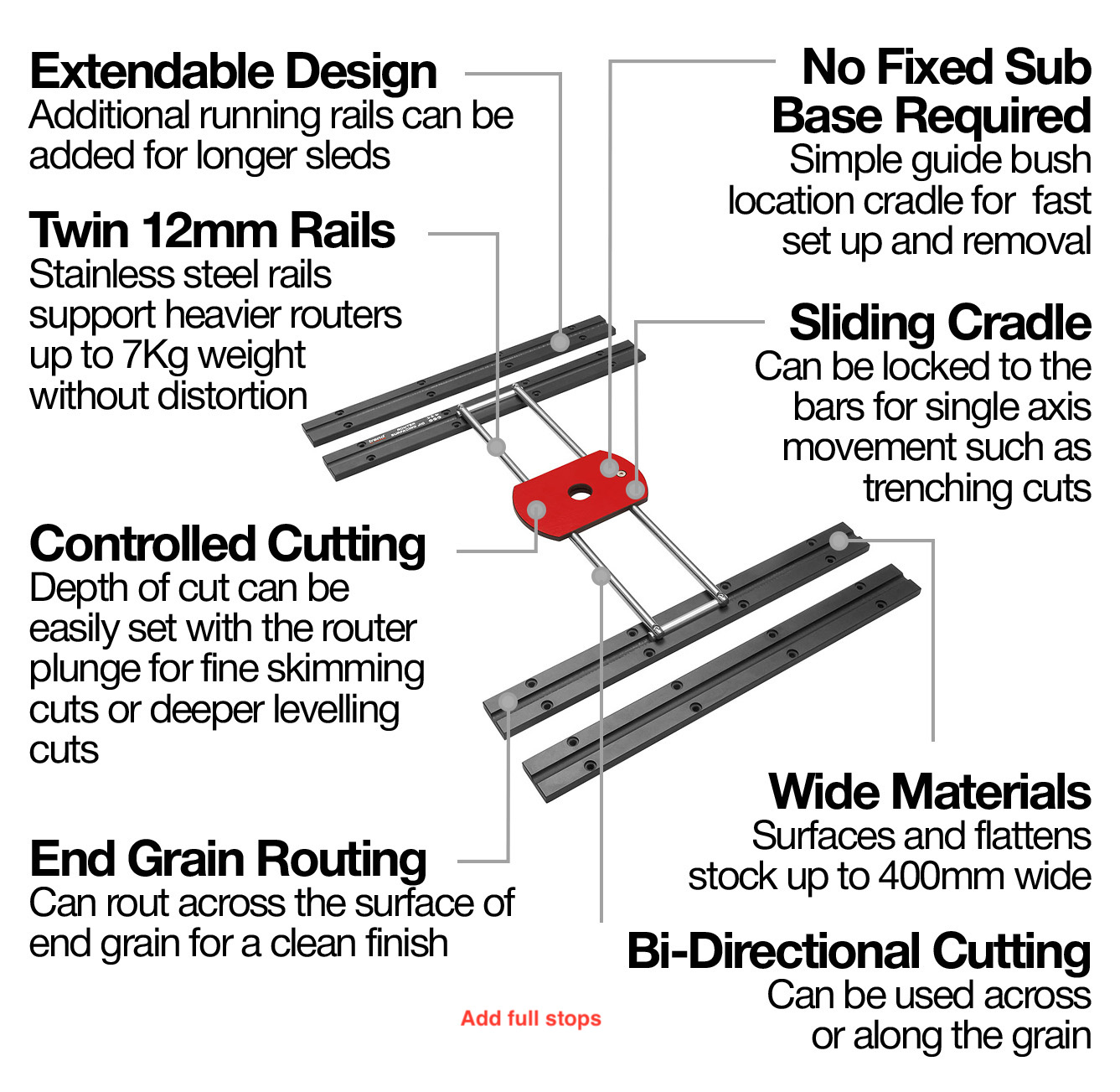

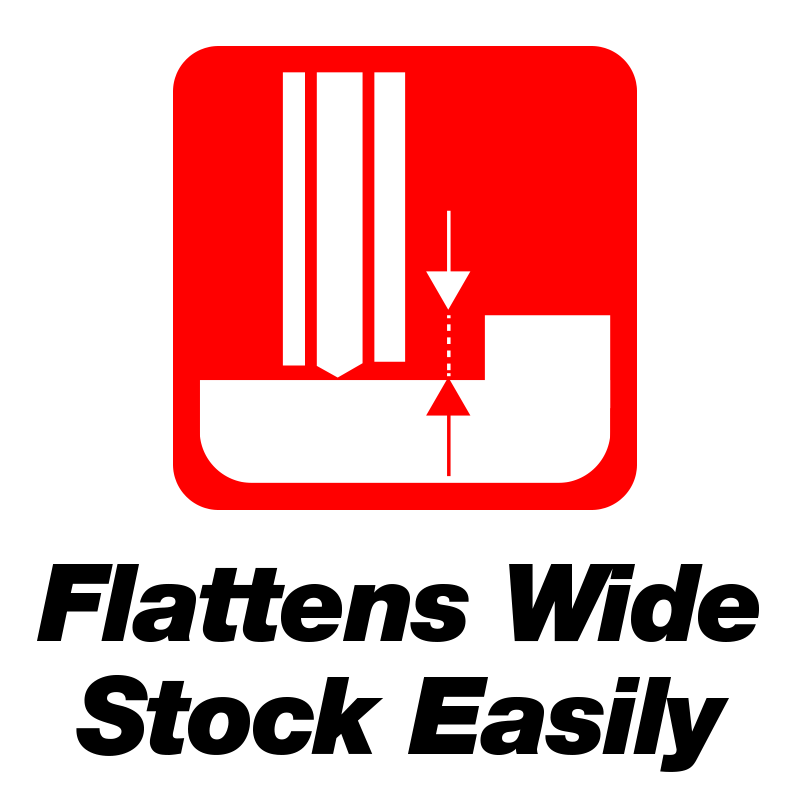

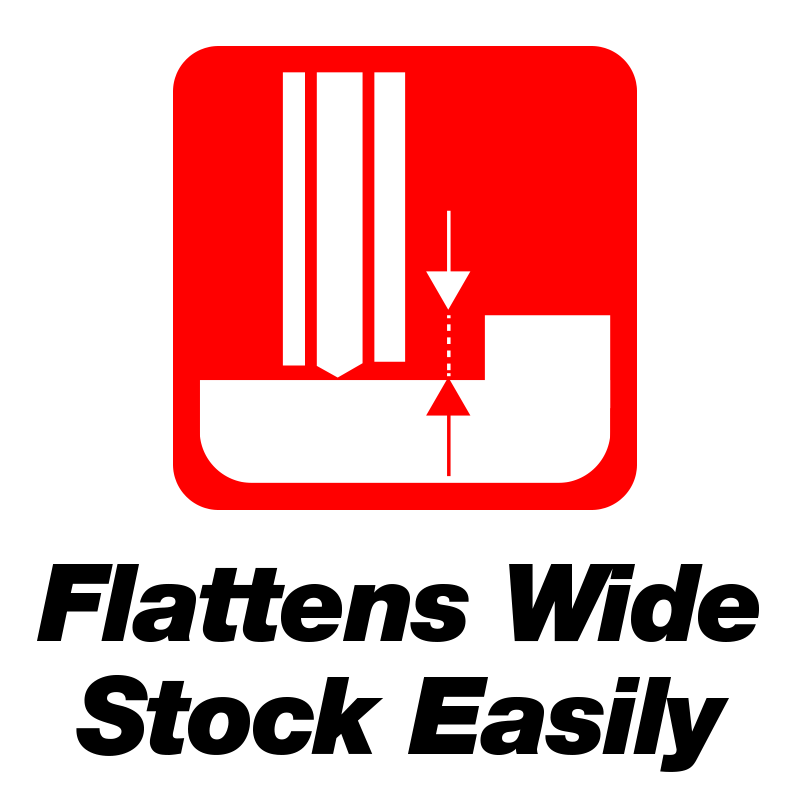

Adaptable router jig for flattening, surfacing and trenching on irregularly shaped and wide material up to 400mm wide. Ideal for fine, skimming cuts and deep, levelling cuts.

Features

Tri-directional cutting across the grain, along the grain, and across the end grain.

Compact Grade HPL Cradle & Rails for precision, strength and durability.

12mm Stainless Steel Rails support routers up to 7kg across materials 400mm wide.

Guide Bush Cradle is compatible with any router using a 30mm guide bush, and requires no additional fixings or sub-base.

Lockable Cradle for single-axis movement. Ideal for trenching cuts.

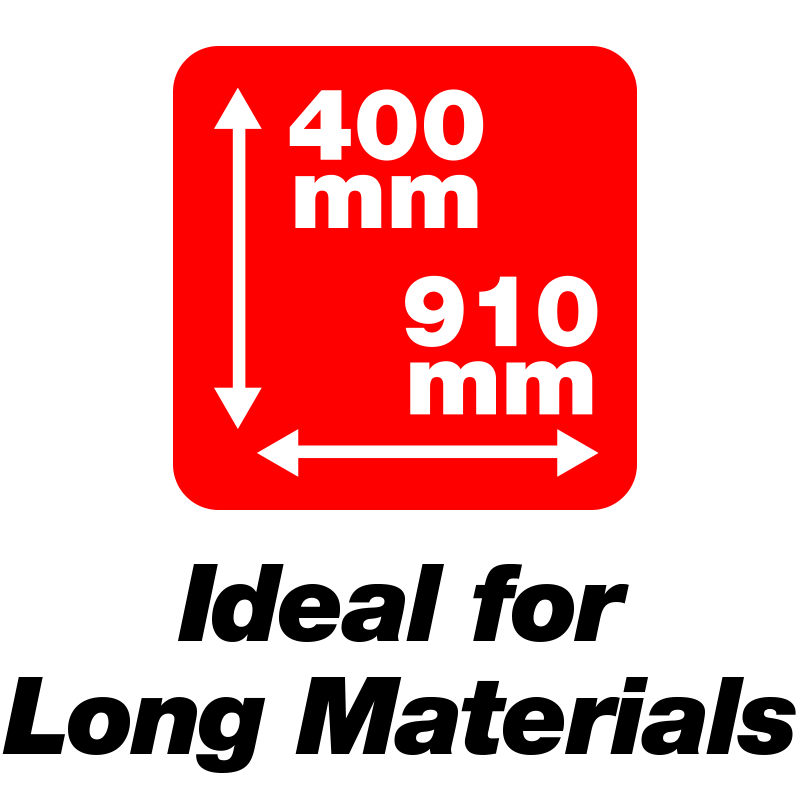

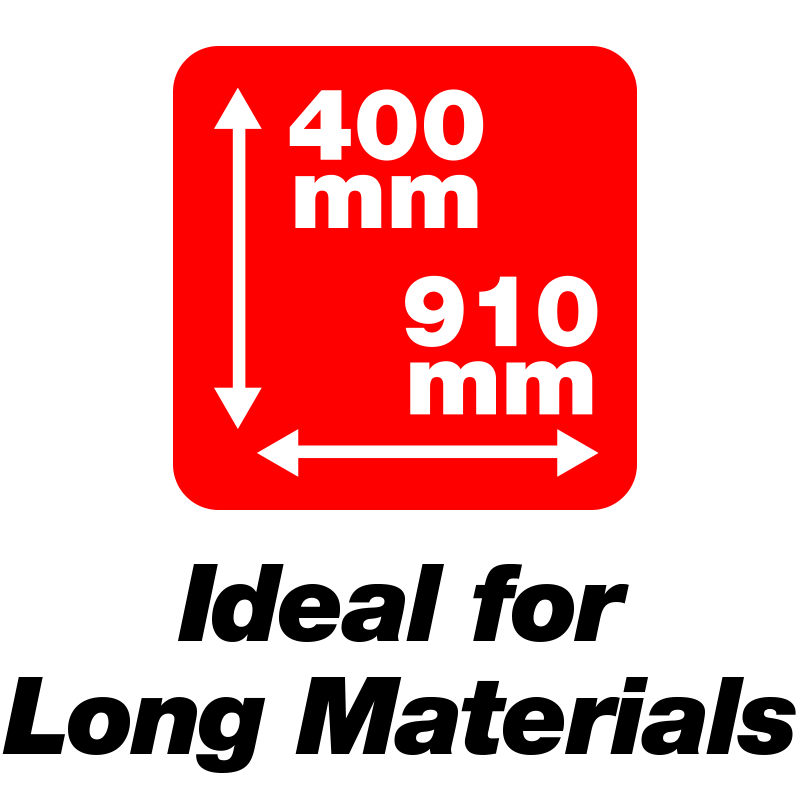

Extendable Design accommodates additional rails for longer materials.

Compact Modular Construction stores easily.

Depth of cut can be easily controlled with the router plunge for fine skimming cuts or deeper levelling cuts.

Requires: router (½”/12mm collet – min.1300W), cutter (½”/12mm shank), and guide bush (30mm diameter).

Details

- Tri-directional cutting across the grain, along the grain, and across the end grain.

- Compact Grade HPL Cradle & Rails for precision, strength and durability.

- 12mm Stainless Steel Rails support routers up to 7kg across materials 400mm wide.

- Guide Bush Cradle compatible with any router using a 30mm guide bush, and requires no additional fixings or sub base.

- Lockable Cradle for single axis movement. Ideal for trenching cuts.

- Extendable Design accommodates additional rails for longer materials.

- Compact Modular Construction stores easily.

- Requires: router (½”/12mm collet – min.1300W), cutter (½”/12mm shank), and guide bush (30mm diameter).

Featured Products

RS/JIG

Router Surfacing Jig

Adaptable router jig for flattening, surfacing and trenching on irregularly shaped and wide material up to 400mm wide. Ideal for fine, skimming cuts and deep, levelling cuts.

Related Products