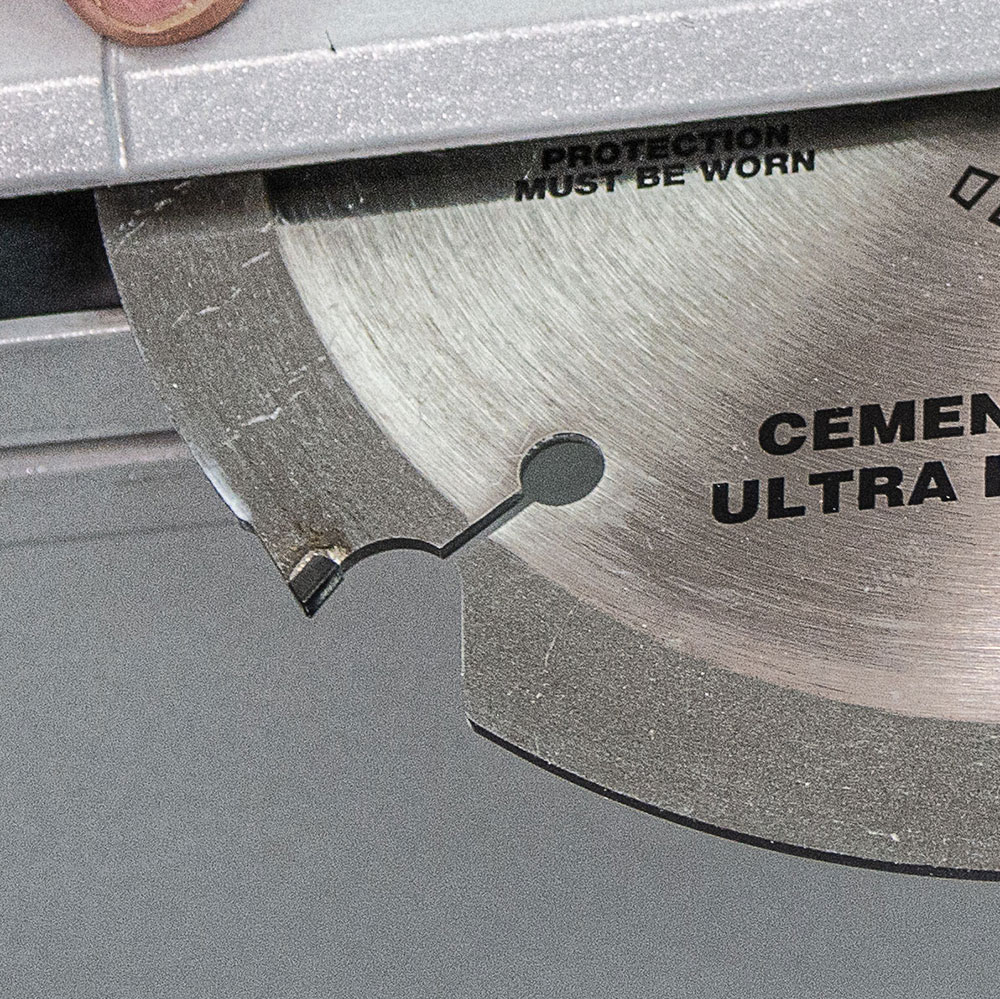

PCD/FSB/2506 - Trend PCD Fibre Cement Circular Saw Blade 250mm x 30mm x 6T

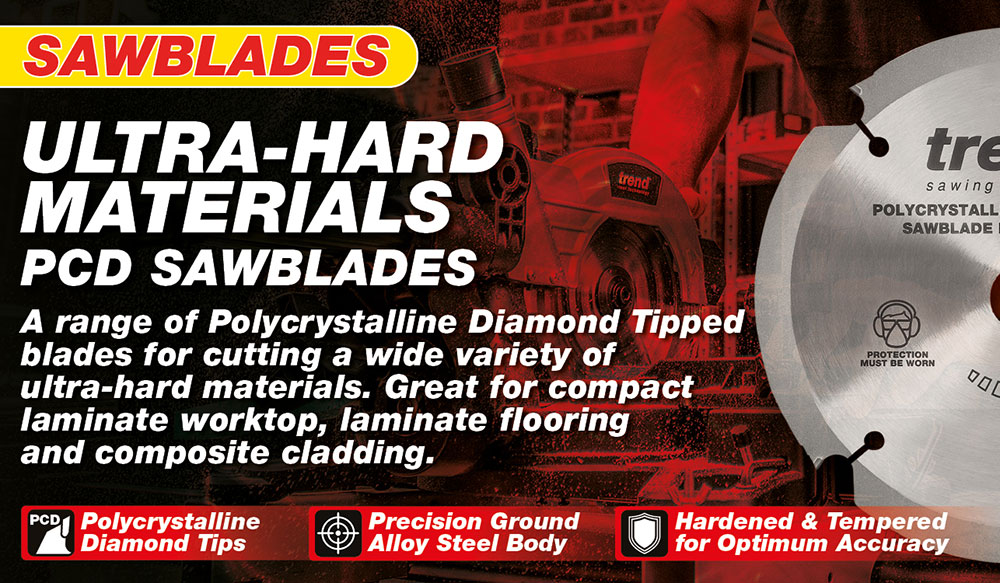

A range of polycrystalline diamond blades for cutting a wide variety of ultra-hard and abrasive materials. For use in circular, plunge, table and mitre saws, Trend PCD Fibre Cement blades are exceptionally durable and retain their cutting edge for longer than TCT alternatives. Ideal for AQUAPANEL®, HardieBacker®, gypsum, composite decking & cladding, laminate flooring, fibre & glass reinforced polymer and compact laminate worktops.

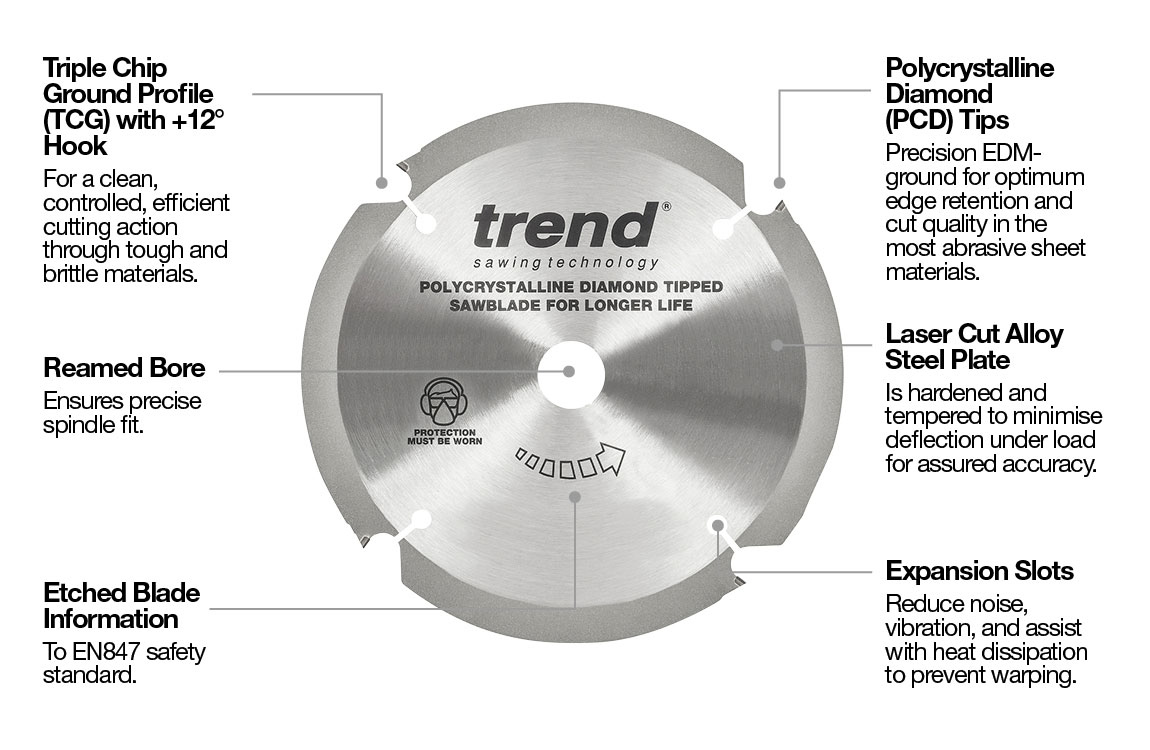

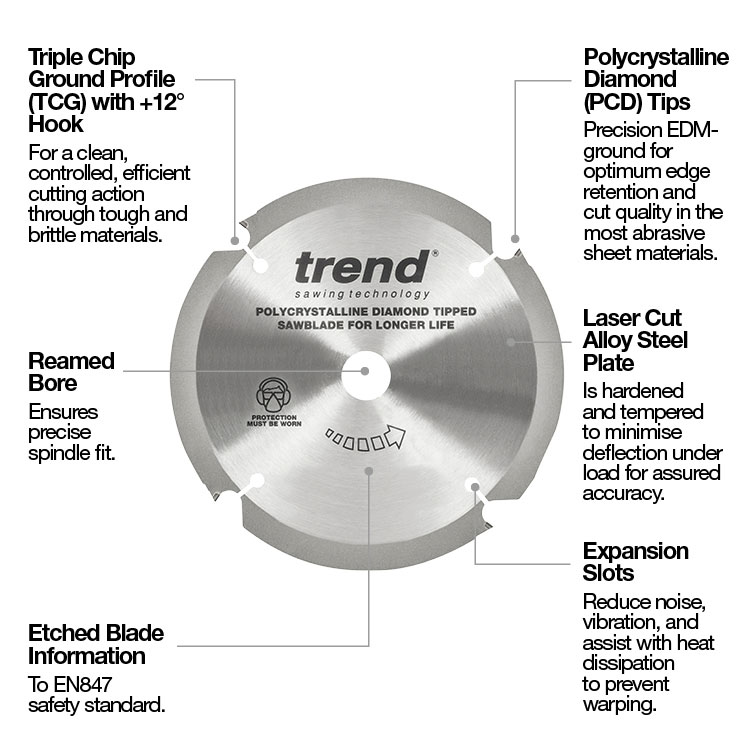

- Precision EDM-ground polycrystalline diamond (PCD) tips for optimum edge retention and cut quality in abrasive sheet materials.

- Triple chip ground (TCG) tooth form with +12° hook for a clean, controlled, efficient cutting action through tough materials.

- Precision ground alloy steel plate to maintain flatness.

- Body hardened and tempered to minimise deflection under load.

- Expansion slots improve heat dissipation to minimise vibration, prevent kick-back and improve cut quality.

- Etched blade information to EN847 safety standard.

- Reamed Bore ensures precise spindle fit.

- Compatible with Dewalt DCS727, Dewalt DCS778, Dewalt DW717, Dewalt DWS727, Dewalt DWS778, Dewalt DW745, Dewalt DWE7491, Dewalt DWE7492, Draper 99258, Einhell TC-SM 2534/1 Dual, Einhell TC-TS 2025/2 U, Einhell TE-CC 2025 UF/S, Einhell TE-CC 250 UF, Hyundai HYTS1800E, Mafell ERIKA 85

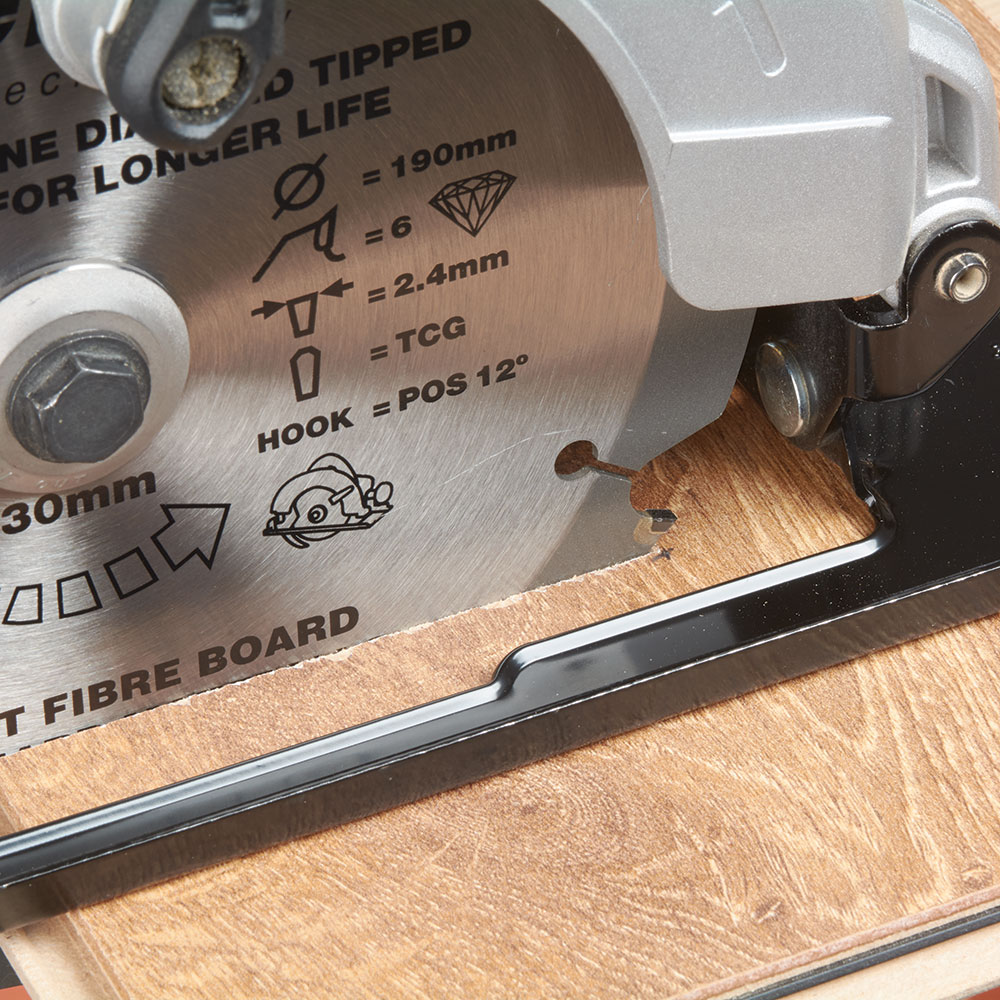

- D1

- 10 inches

- D1

- 250 mm

- Bore

- 30 mm

- Kerf

- 2.4 mm

- Plate thick

- 1.6 mm

- No. of Teeth

- 6

- Tooth form

- TCG

- Hook

- 12 degrees

- Quick Selector No.

- 25.1

- Cut Finish

- Coarse

- Max rpm

- 85000

It is recommended that the blade should not project more than 1mm out of bottom of substrate.

no spare products